Advanced caster design is revolutionizing the way equipment and products are safeguarded across diverse industries. These thoughtfully engineered components have become integral to modern industrial mobility, offering maximum protection and operational efficiency for sensitive and valuable assets. Early in the decision-making process, businesses are strongly encouraged to explore the benefits of shock isolating casters to mitigate vibration and minimize damage during equipment transfer or daily activity.

Modern casters are no longer just about moving objects from one place to another—they’re about preserving equipment integrity, reducing repair frequency, and providing a strategic advantage in environments where every detail counts. The fusion of innovation with functionality ensures that the lowest risk of damage and highest efficiency are always attainable.

With the growth of automation and process optimization, investment in advanced caster solutions has outgrown its traditional role, encompassing the needs of sectors such as healthcare, manufacturing, and logistics. Every element, from material choice to embedded technology, plays a critical part in delivering reliability and value over the long term.

The importance of matching caster capabilities to specific requirements is evident in studies from industry sources. Selecting the right mobility components is essential to minimize downtime and avoid costly repairs.

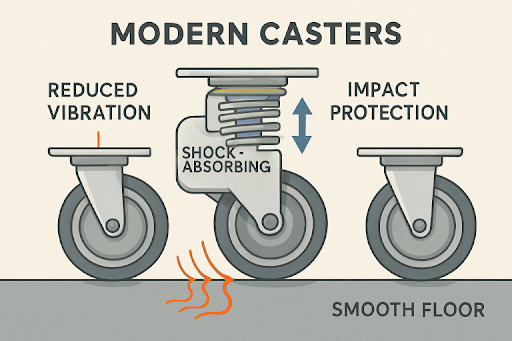

Shock-absorbing casters are specifically designed to mitigate the hazards associated with transporting delicate or sensitive instruments over uneven flooring or through active environments. Their unique ability to minimize the transfer of shocks and vibrations helps prevent internal failures and structural degradation in vital machines and tools.

This technology is especially indispensable in laboratories, electronic assembly plants, and medical environments where stability and gentle handling are paramount. Choices in this category often include spring-loaded mechanisms and resilient wheel compounds that absorb kinetic energy, keeping valuable assets secure even in challenging conditions.

Precision Bearings for Smooth Operation

The use of sealed ball bearings and precision roller bearings in caster designs is fundamental for smooth and seamless movement. Precision bearings reduce friction between moving parts, thereby decreasing wear and extending the service life of both the casters and the equipment.

Sealed units further protect against debris, dust, and other contaminants, making them ideal in environments where cleanliness and equipment reliability cannot be compromised. Bearing integrity is key to operational excellence and minimizing unexpected downtime costs.

Specialized Casters for Industry-Specific Needs

Today’s industries require more than just generic solutions—customized caster designs have emerged to address unique and intricate challenges. For example, in hospitals and clinics, casters with threads and body guards prevent the entanglement of debris, hair, and other contaminants, thus supporting rigorous hygiene standards and equipment cleanliness.

Similarly, casters designed for manufacturing floors or warehouses often feature increased load capacities and ruggedized components, ensuring safety even under extreme weights and frequent movement routines. Selecting industry-specific casters maximizes both protection and operational continuity.

Noise Reduction and Floor Protection

An often-overlooked advantage of advanced caster design is its ability to suppress noise and preserve floors. Thanks to innovative, non-marking wheels and engineered tread patterns, modern casters reduce rolling noise and eliminate surface marks, which is essential for maintaining a quiet atmosphere in hospitals, schools, and office environments.

This translates to reduced disruption, a safer environment, and long-term savings on facilities maintenance.

Enhanced Load Capacity and Durability

Heavy-duty equipment demands robust caster systems that can safely bear significant weights without risking collapse or malfunction. Advanced casters utilize high-grade polyurethane, reinforced steel, and composite materials to achieve optimized durability and load management, ensuring the safe transportation of even the heaviest inventory or machinery.

The result is fewer replacements, lower maintenance costs, and a stable foundation for critical assets during movement.

Integration of Smart Technology

The digitization of industrial assets extends to casters through the introduction of embedded sensors and IoT capabilities. Modern smart casters are capable of providing real-time insights about load weight, movement frequencies, wear levels, and potential maintenance needs.

This predictive data enables proactive care, refined asset management, and ensures that corrective actions are taken before a costly incident can occur. Such smart systems are transforming casters from passive to intelligent infrastructure elements within logistics and manufacturing sectors.

Customization for Optimal Performance

One of the hallmarks of the latest advancements in caster technology is the ability for operators to custom-match products to their specific use cases—whether it be material sensitivity, hygiene, static management, or floor condition. Depending on specific applications, customization can include proprietary wheel composites, fine-tuned bearing systems, and modified frames.

This approach ensures optimal movement, maximum asset protection, and tailored solutions for every task, aligning caster functionality with strategic operational goals.

Conclusion

Invest in contemporary caster technology to ensure lasting protection, efficient operations, and lower equipment repair costs. From shock absorption to smart tracking, each innovation within caster design builds upon a legacy of protecting valuable equipment and optimizing workflows. Staying informed and leveraging advanced mobility solutions is crucial for any business committed to maintaining asset integrity and achieving operational success.