Every flight, from commercial aircraft to space probes, relies on precise engineering, where even small components, such as fasteners, play a critical role in safety and resilience. Fastener design, material selection, and manufacturing quality directly influence performance across fuselages, wings, engines, and landing gear. As aerospace systems evolve, manufacturers increasingly rely on specialized supply chains and top fastener distributors to meet stringent requirements for strength, weight reduction, and consistency. Advancements in materials science, tighter quality standards, and ongoing innovation have made fasteners essential to overall aerospace reliability. The industry demands lighter, stronger solutions for composites and digital monitoring, driving design improvements. Regulatory guidance and research underscore the complexity of fastener selection, emphasizing the need for collaboration among engineers, suppliers, and certifiers to overcome technical challenges and promote safer, more sustainable air and space travel.

Importance of Fasteners in Aerospace

Fasteners are responsible for distributing loads across the entire structure of an aircraft or spacecraft. Their positioning and type are critical, as they determine whether stress is evenly managed or localized—potentially leading to issues such as fatigue cracks and structural failures. In high-stress areas such as wings and fuselage sections, improper fastener installation can compromise safety and operational life cycles. According to the NASA Aeronautics Research Mission Directorate, selecting proper fasteners and ensuring their correct installation remain top priorities in both design and maintenance protocols.

Material Selection for Aerospace Fasteners

Aerospace fasteners are selected based on strength, weight, and resistance to extreme environmental factors. Key materials include Titanium for its strength-to-weight ratio and corrosion resistance in critical flight applications; Inconel, a superalloy ideal for high-temperature engine assemblies; and Stainless Steel for moderate strength in fuselage applications. The choice strikes a balance between structural needs and environmental risks to ensure long-term reliability.

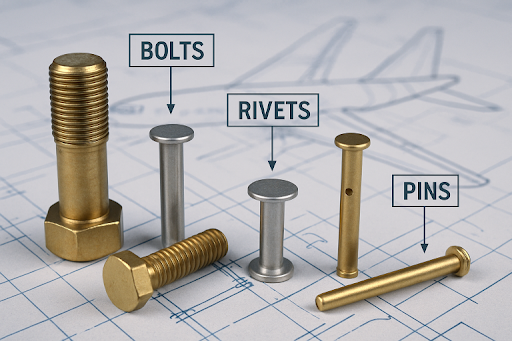

Types of Fasteners Used in Aerospace

Aerospace engineers utilize various fastener types based on operational requirements. Bolts are used for removable joints in both temporary and permanent assemblies. Rivets establish permanent joints and are ideal for aerodynamic surfaces. Pins are crucial for precise alignment and disassembly. The choice of fastener affects inspection, accessibility for repair, and system weight.

Quality Standards and Certifications

The aerospace industry is highly regulated, with fasteners required to meet stringent quality standards set by organizations such as the FAA and EASA. Key requirements include complete material traceability, comprehensive documentation from raw material certifications to testing data, and adherence to specific aerospace grades and manufacturing protocols. These measures support maintenance cycles and facilitate the investigation of fastener-related failures.

Technological Advancements in Fastener Design

Industry innovation has spawned smart fasteners embedded with sensors that can monitor real-time loads and detect loosening or failures, vastly improving predictive maintenance models. Digital fastener management systems now track installation torque, tightening cycles, and environmental changes during operation, reducing the risk of human error and facilitating detailed analytics throughout the aircraft life cycle. These advancements are heralded not only by manufacturers but also by maintenance crews and regulators intent on further raising aerospace safety standards.

Challenges in Fastener Application

Engineers face numerous real-world obstacles when selecting and installing fasteners, including mitigating the effects of vibration, accommodating material expansion or contraction due to temperature shifts, and protecting against corrosion in humid or saline environments. Meticulous installation methods, ongoing inspections, and advancements in anti-corrosion coatings are critical to ensuring long-term fastener performance and, by extension, aircraft safety and durability.

Future Trends in Aerospace Fastening

As aerospace manufacturers shift to lightweight composites and hybrid structures, fastener design must continually evolve. Thread geometry, material pairing, and joint design are being reimagined to provide secure attachment without adding unwanted weight. Additive manufacturing and rapid prototyping are revolutionizing the production of custom fastener solutions, enabling greater design flexibility and significantly shorter turnarounds from prototype to production. The fusion of sensor technology and materials science points toward an era of “smart” fasteners, which will offer unprecedented insight into aircraft health monitoring systems.

Conclusion

Fasteners serve as the backbone of every aerospace endeavor, from prototype development to operational fleet maintenance. Their importance in maintaining structural integrity cannot be overstated—they guarantee the safety, performance, and innovation that define the modern aerospace industry. Continued advancement in design, material engineering, and real-time monitoring will ensure these small but mighty components remain at the forefront of aerospace progress for generations to come.